Technology brief

Regenerative Catalytic Oxidizer (RCO) is an organic waste gas treatment equipment which combines low temperature catalytic oxidation with thermal storage technology. The equipment is a new type of volatile organic compounds processing equipment developed on the basis of RTO technology.

Technological principle

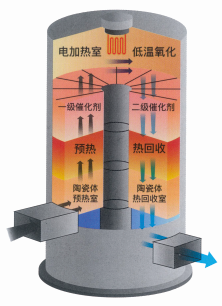

Organic waste gas was heated through ceramic filled layer, and the temperature almost reached the set temperature of catalytic oxidation. Some of the organic waste gas was oxidized and decomposed. The exhaust gas continued to rise through the electric heating zone and maintained at the set temperature. After entering the catalytic layer, the catalytic oxidation reaction at lower temperature (250 C -300 C) generated CO. Two And H Two O, and release a lot of heat to achieve the desired effect. After catalytic oxidation, gas enters other ceramic filled layers, and heat is released to the atmosphere. After purification, the exhaust temperature is only slightly higher than that before the exhaust gas treatment. The system operates continuously and automatically switches. Through the rotary valve operation, all ceramic filling layers are completed by heating, cooling and purifying cycle steps, and heat is recovered.

Trial object

■It is suitable for painting production lines of automobile, shipbuilding, bicycles, motorcycles, household appliances, containers and other production plants.

■It is suitable for waste gas treatment of petroleum, chemical, rubber, paint, paint, shoes, viscose, plastic products, tin cans, printing inks, cables and enameled wires.

■It can be applied to the enterprises that need heat recovery or waste gas treatment of drying lines, and can be used for drying energy lines, so as to achieve the purpose of energy conservation.

■The types of organic matter that can be treated include benzene, ketones, esters, aldehydes, phenols, alcohols, ethers and hydrocarbons.

Technical characteristics

■It is suitable for high concentration (greater than3000mg/m). Three Organic waste gas.

■It can remove many organic pollutants simultaneously.

■The purification efficiency is high, generally more than 99%.

■Low reaction temperature and NOx emission reduction.

■Energy saving and emission reduction, compared with direct combustion, save running cost 25%~40% and heat recovery efficiency up to 95%.

■The equipment is small in size, compact in design and small in area.