Technology brief

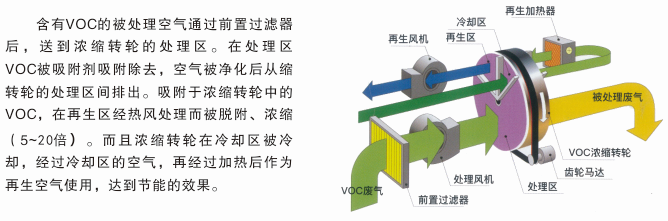

The zeolite wheel adsorption thickening device adopts three consecutive procedures, one is adsorption and the other is concentrated and incinerated, which is mainly used for the treatment of organic waste gas, especially for the treatment of organic waste gas. It is suitable for large air volume and low concentration occasions. The adsorption device is made of ceramic fiber as the base material, and is made into a honeycomb large disc wheel system. Hydrophobic zeolite was used as adsorbent. The zeolite runner adsorption concentrator is mainly composed of exhaust gas pretreatment system, molecular sieve runner concentrated adsorption system, The system consists of desorbing system, cooling and drying system and automatic control system. There is usually a post-processing system after the runner.

Applicable object

■It is suitable for petrochemicals, fine chemicals, spraying, packaging and printing, medicine and pesticide manufacturing, semiconductor and electronic products manufacturing, wood-based panel and wooden furniture manufacturing, leather, enameled wire, shoemaking, coating, ink, adhesive production, metal casting and so on.

■The types of organic matter that can be treated include hydrocarbons, benzene alcohols, ketones, phenols, aldehydes, esters, amines, nitriles and cyanides.

Technical characteristics

■The adsorption and desorption efficiency is high.

■The pressure drop of VOCs adsorbed by zeolite wheel is very low, which greatly reduces the power consumption.

■So that the original high air volume and low concentration VOCs exhaust gas can be converted into low air volume and high concentration exhaust gas, and the concentration multiple can reach 5-20 times, which greatly reduces the specification of post-processing equipment and lower running cost.

■The whole system is automatic control and modular design with small footprint.