This product uses honeycomb activated carbon as adsorbent, combined with the principles of adsorption purification, desorption, regeneration, concentration of VOCs and catalytic combustion, and develops an organic waste gas treatment equipment with high volume, medium and low concentration.

Catalytic combustion is a purification method using catalysts to oxidize and decompose combustible components in harmful gases at lower temperatures. For HC and organic solvent, steam is decomposed into carbon dioxide and water and heat is released.

Catalytic combustion requires the mixture of harmful gases to be cleaned and uniformly preheated to the required ignition temperature of the catalyst, so that the combustible components in the harmful gases are oxidized and exothermic.

Working principle

The essence of activated carbon adsorption is to adsorb the organic solvent in low concentration and large volume of exhaust gas into activated carbon and concentrate it by using the characteristics of activated carbon adsorption. It is a physical process not to dispose of organic solvents.

The essence of catalytic combustion desorption is to use the hot air of catalytic combustion to heat the organic solvent adsorbed in the activated carbon, so that it can reach the boiling point of the solvent, so that the organic solvent can be removed from the activated carbon, and the high concentration waste gas is introduced into the catalytic combustion reactor. At the catalytic combustion temperature of 250 C, the oxidation reaction is transformed into harmless water and carbon dioxide into the atmosphere through the action of the catalyst. It is a chemical reaction process, not the open flame combustion, and it can completely solve the two pollution during desorption.

Activated carbon adsorption and catalytic combustion desorption are effective combination of the above two advantages. That is, activated carbon is used for adsorption and concentration. Activated carbon When the adsorption reaches saturation, electric heating is used to start the catalytic combustion equipment, and the activated carbon adsorption bed is heated locally by hot air. When the catalytic combustion reaction bed is heated to 250 degrees C and the activated carbon adsorption bed reaches 60-110 degrees centigrade, the high concentration exhaust gas desorption from the adsorption bed can be oxidized in the catalytic reaction bed. After reaction, the high temperature gas is exchanged through the heat exchanger. After heat transfer, the gas is partly reused and sent to the activated carbon adsorption bed for desorption, and the other part is discharged into the atmosphere. After the heat transfer from the heat exchanger, the temperature of the exhaust gas is increased rapidly, so that the catalytic combustion device and desorption can be operated at low or no power.

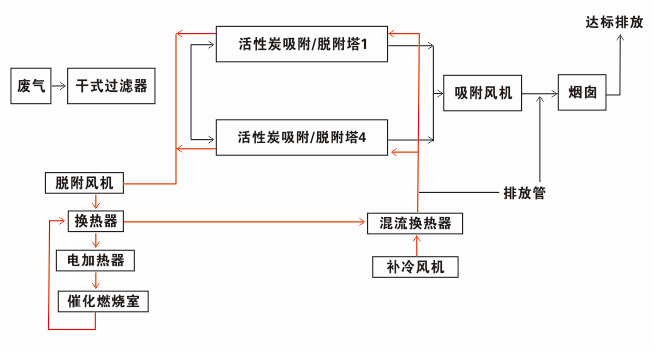

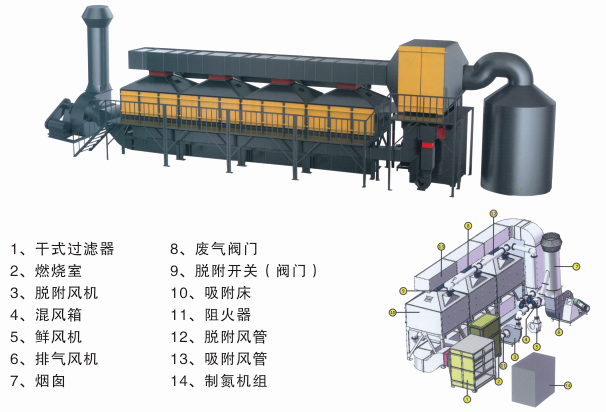

Technological process

Organic waste gas adsorption and purification process: exhaust gas is first removed by dry filter, and then evenly activated by activated carbon adsorption bed. Pollutants in the exhaust gas are adsorbed on the surface of activated carbon, and the purified gas is discharged through the chimney.

Activated carbon desorption regeneration and catalytic combustion process: when the adsorption reaches saturation, the regeneration hot air is sent to the adsorption through the valve switch. The activated carbon is heated by the bed, and the activated carbon is heated to resolve the higher concentration of organic gas, and the catalytic combustion bed is introduced by the desorption circulating fan. The gas passes through catalytic combustion to produce harmless gases such as carbon dioxide and water and some of the heat. The heat is reused for the regeneration of activated carbon in the adsorption bed. whole The adsorption and catalytic combustion process is controlled automatically by PLC.

Process analysis

Activated carbon is a kind of material with strong adsorption properties. Its structural characteristics enable activated carbon to absorb relatively high quality. And the amount of absorption is enormous. In our daily life, we also use these substances to absorb gas. therefore In industrial waste gas absorption, activated carbon is also used, activated carbon adsorption desorption catalytic combustion technology, is a great play. The high quality of activated carbon.

Adsorption desorption process of activated carbon for catalytic combustion

1、Adsorption: organic waste gas is removed from the solid particulate matter through the filter, from bottom to top into the adsorption tank, and the organic matter is captured and adsorbed by activated carbon.

And concentrated and purified air is discharged into the atmosphere from the upper part of the tank through the main fan.

2、desorption: when activated carbon adsorbed organic matter reached saturation state, stop inhaling organic waste gas. The activated carbon bed is sent upward into the steam to blow off, and the organic matter is expelled from activated carbon, that is, desorbing. Activated carbon in tank can restore its activity, that is, regeneration.

3、Hot air drying and cooling: in the activated carbon layer after steam desorption, about 80~90% of the steam condensate is filled with activated carbon. The pores thus reduce the activity of the carbon layer. Therefore, the hot air is used to dry the carbon layer. Then turn off the steam valve and turn it into room temperature. When the gas is cooled to about 25 degrees, activated carbon is restored to its original form for recycling.