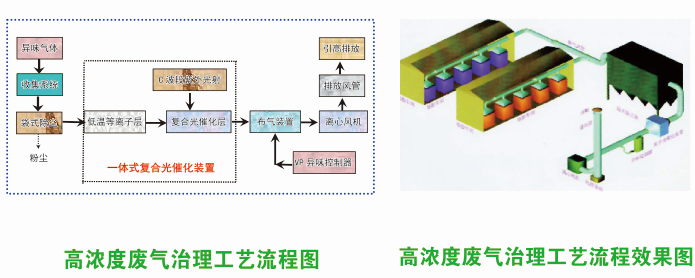

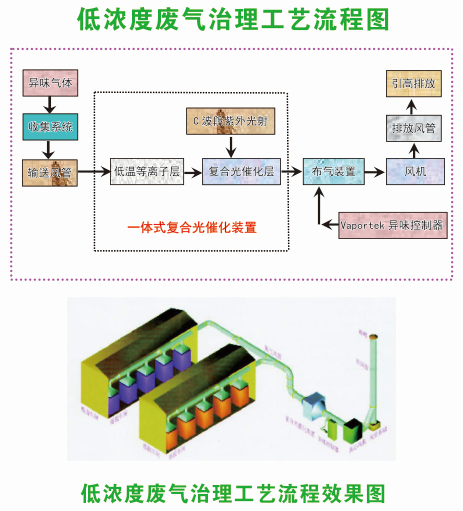

Depending on the nature and classification of exhaust gases, different treatment processes should be selected:

1、high concentration waste gas treatment process: bag filter + composite photocatalysis device + low temperature plasma + dry neutralization and deodorization.

2、low concentration waste gas treatment process: composite photocatalysis device + low temperature plasma + dry neutralization and deodorization.

Process description

The odorous gas generated during the production process is collected through the casing and the air duct, and is pumped to the waste gas treatment units under the action of the centrifugal fan to purify so as to achieve the goal of environmental protection and emission.

The first step: the collected exhaust gas contains more dust and is pumped to the bag filter (the main function is to remove more than 90% of the dust from the waste gas).

The second step: the waste gas treated by the bag filter is sent to the pretreatment section, which is pretreated by the interception, collision, diffusion and absorption of the fiber filtration section and the carbon fiber homogenization section (the main function is to remove small particles and some harmful components in the exhaust gas).

The third step: the exhaust gas from pretreatment section is sent to the Composite Photocatalytic nickel net unit, and the TiO is formed under the C band ultraviolet lamp. Two Photocatalytic oxidation is active hydroxyl (OH) and other active oxides (.O-, OOH, H). Two O Two The result of joint action. The OH group generated on the surface of TiO: is highly reactive and has higher reaction energy than all kinds of chemical bond energy in organic compounds, plus.0. Two -. OOH, H Two O Two The synergistic action of active oxidizing substances can rapidly and effectively decompose organic matter. (main function: removing benzene, toluene, xylene, hydrogen sulfide and non methane total hydrocarbon in waste gas);

The fourth step: the exhaust gas after pretreatment is sent to the low temperature plasma excitation region. Under the accelerating effect of the electric field, high energy electrons are generated. When the average energy of the electrons exceeds the chemical bond energy of the target molecules, the molecular bonds break up to achieve the purpose of eliminating gaseous pollutants. (main function: removing benzene, toluene, xylene, non methane total hydrocarbon and VOCS in waste gas);

The fifth step: the former three levels of pretreated hetero gas still leave a large odor pollution problem. At this time, the advanced odor control technology introduced by our company is used to install the Vaportek odor control box at the inlet of the centrifugal fan (negative pressure side), and the negative pressure of the fan will bring the deodorant particles in the odor control box, and quickly catch the odor gas in the air and wrap the odor particles. Vaportek particles are natural oil deodorizing molecules, which are covalently bound with odor molecules through intermolecular nonpolar interactions, thereby greatly stabilizing the molecule, reducing its activity and irritation, so as to achieve a complete removal of odor. (main function: removal of odor from exhaust gas).

The sixth step: the treated exhaust gas is discharged through the chimney (15m above height).

Process description

The odorous gas generated in the production process is collected through the casing and the air duct, and is pumped to the treatment units under the action of the centrifugal fan, so as to achieve the goal of environmental protection and emission.

The first step: exhaust gas is pumped to the pretreatment section, through the fiber filter section and the carbon fiber homogenization section of the interception, collision, diffusion and absorption pretreatment (the main role: toxic and harmful components in the exhaust gas removal rate of more than 65%);

The second step: after the pretreatment waste gas is sent to the low temperature plasma excitation region, the high energy electrons are generated under the accelerating effect of the electric field. When the average energy of the electrons exceeds the chemical bond energy of the target molecules, the molecular bonds break up to achieve the purpose of eliminating gaseous pollutants. (main functions: removal of benzene, toluene, xylene, hydrogen sulfide, non methane total hydrocarbons and VOCS in some exhaust gases).

The third step: the exhaust gas from pretreatment section is sent to the Composite Photocatalytic nickel net unit, and the TiO is formed under the C band ultraviolet lamp. Two Photocatalytic oxidation is active hydroxyl (- OH) and other active oxidizing substances (.O Two -. OOH, H Two O Two The result of joint action. At TiO Two The.OH group generated on the surface is highly reactive and has higher reaction energy than all kinds of chemical bond energy in organic compounds, plus.O. Two -.00H, H Two O Two The synergistic action of active oxidizing substances can rapidly and effectively decompose organic matter. (main function: removing benzene, toluene, xylene and non methane total hydrocarbons in some exhaust gases).

The fourth step: the former three levels of pretreated hetero gas still leave a large odor pollution problem. Using the advanced deodorizing technology introduced by our company, the Vaportek odor control box is installed at the inlet of the centrifugal fan (negative pressure side), and the negative pressure of the fan generates the deodorant particles in the odor control box, and quickly captures the odor gas in the air and encapsulates the odor particles. Vaportek particles are natural oil deodorizing molecules, which are non covalently bound to the odor molecules through intermolecular nonpolar interactions, thus greatly stabilizing these molecules, reducing their activity and irritation, so as to achieve a complete removal of odor. (main function: removal of odor from waste gas).

The fifth step: the treated exhaust gas is discharged through the chimney (15m above height).